Expanded Discrete Migratory Bird Optimizer for Circular Disassembly Line Balancing with Tool Deterioration and Replacement

Keywords:

Circular disassembly line balancing, Tool deterioration, Tool replacement, Migratory bird optimizerAbstract

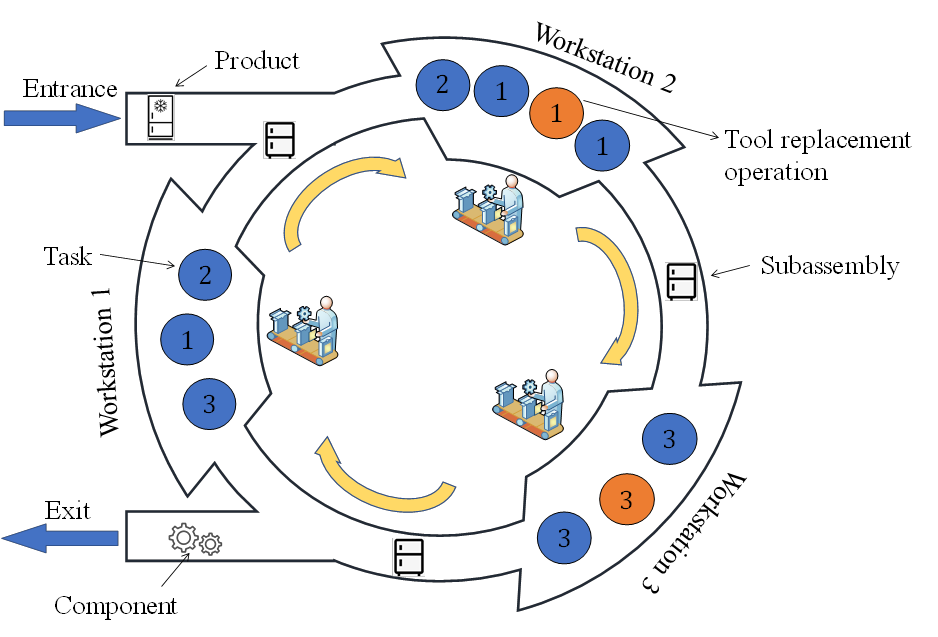

As an important part of the closed-loop supply chain, the improper disposal of end-of-life (EOL) products reduces overall system efficiency and causes environmental pollution. Thus, it is crucial to dispose of EOL products timely and effectively. Disassembly is a key method for recycling EOL products. During mass disassembly, tools suffer deterioration due to long-term wear and corrosion, increasing processing time for disassembly tasks. To prevent continuous tool deterioration, a tool replacement operation is proposed. Therefore, this work proposes a circular disassembly line balancing with tool replacement, aiming to maximize the disassembly profit by improving the disassembly efficiency as much as possible under the load balance of individual workstations. In this work, a crossover as well as four mutations are provided so as to discretize and extend the original migratory bird optimizer to the solution of the circular disassembly line balancing with tool deterioration and replacement. In the experimental phase, the correctness of the model is verified by the CPLEX solver. The effectiveness of the proposed algorithm is given by comparison experiments due to the CPLEX solver as well as other optimization algorithms. The experimental results show that the proposed algorithm is more effective than the discrete fruit fly optimization algorithm, discrete whale optimization algorithm, and salp swarm algorithm.

Downloads

Downloads

Published

License

Copyright (c) 2025 International Journal of Artificial Intelligence and Green Manufacturing

This work is licensed under a Creative Commons Attribution 4.0 International License.