Towards Robust Identification of Rail Short-Wavelength Irregularities: A Multi-Modal Fusion of Vibration and Profile Data

Abstract

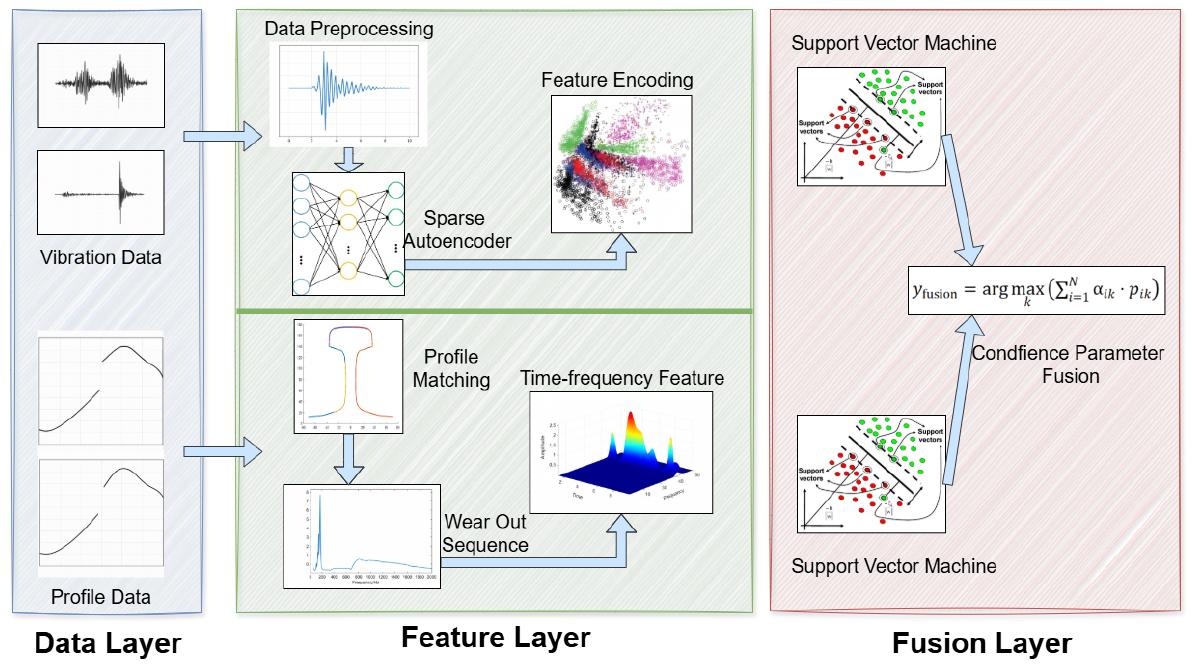

Short-wavelength rail irregularities (SWRIs) are localized geometric deviations that evolve under periodic wheel loads and can compromise operational safety. Vibration-only inspection is prone to noise and response ambiguity, whereas profile-only inspection lacks temporal dynamics of wheel--rail interaction. We propose a multi-modal framework that fuses axle-box vibration sequences with high-resolution rail profile data. On the vibration side, features are learned via stacked autoencoders (SAE); on the profile side, measured contours are registered to a standard template, transformed into wear sequences via Dynamic Time Warping (DTW), and compressed with Principal Component Analysis (PCA). Two kernel SVMs (KSVMs) trained on the respective modalities are aggregated through a class-dependent confidence fusion. On a 100~m laboratory rail with simulated grinding (F1), spalling (F2), abrasion (F3), and normal (F4), we collect 200 paired samples and show that the fusion model markedly reduces misclassification, achieving accuracies of 87.5\% (F1), 100\% (F2), 93.3\% (F3), and 94.1\% (F4), with overall gains ranging from 7.1\% to 47.7\% over single-source baselines. The approach provides a principled path to robust, intelligent rail condition monitoring.

Downloads

Downloads

Published

License

Copyright (c) 2025 International Journal of Artificial Intelligence and Green Manufacturing

This work is licensed under a Creative Commons Attribution 4.0 International License.